Hydroxypropyl methylcellulose (HPMC) is an important nonionic cellulose ether widely used in construction, pharmaceuticals, food, and daily chemicals. Viscosity is a key indicator for evaluating the quality and applicability of HPMC. It not only reflects the rheological properties of its solution but is also directly related to its thickening, water retention, and film-forming properties. To ensure consistent product quality, viscosity measurement must be performed using a scientific and standardized viscosity test method.

1. Test Principle

HPMC dissolves in water to form a transparent or translucent solution. Its viscosity depends primarily on the degree of polymerization, degree of substitution, and solution concentration. Viscosity testing characterizes the flow properties of an HPMC solution by measuring the internal friction of the solution during flow at a specific temperature. Measurements are typically performed using a rotational viscometer (Brookfield type) or a capillary viscometer. The rotational method is more commonly used, as it provides a more intuitive understanding of the shear-thinning properties of the solution at different rotational speeds.

2. Common Standards and Test Conditions

Currently, HPMC viscosity testing is primarily based on the following:

Chinese Standard: GB/T 12000 “General Test Methods for Cellulose Ethers”

US Standard: ASTM D1347 “Standard Test Methods for Cellulose Ether Solutions”

Industry practice: Viscosity is measured using a 2% aqueous solution at 20°C using a Brookfield rotational viscometer.

The test solution concentration is generally 2% (mass fraction), but different HPMC grades may also require calibration at 1%, 2%, or higher concentrations. The test temperature must be strictly controlled at 20±0.1°C, as temperature fluctuations can significantly affect viscosity readings.

3. Experimental Procedure

3.1. Reagent and Instrument Preparation

Precision analytical balance (0.1 mg accuracy)

Brookfield rotational viscometer (commonly available LV series)

3.2. Constant temperature water bath or temperature-controlled environment

Purified water (meets GB/T 6682 Grade III water requirements)

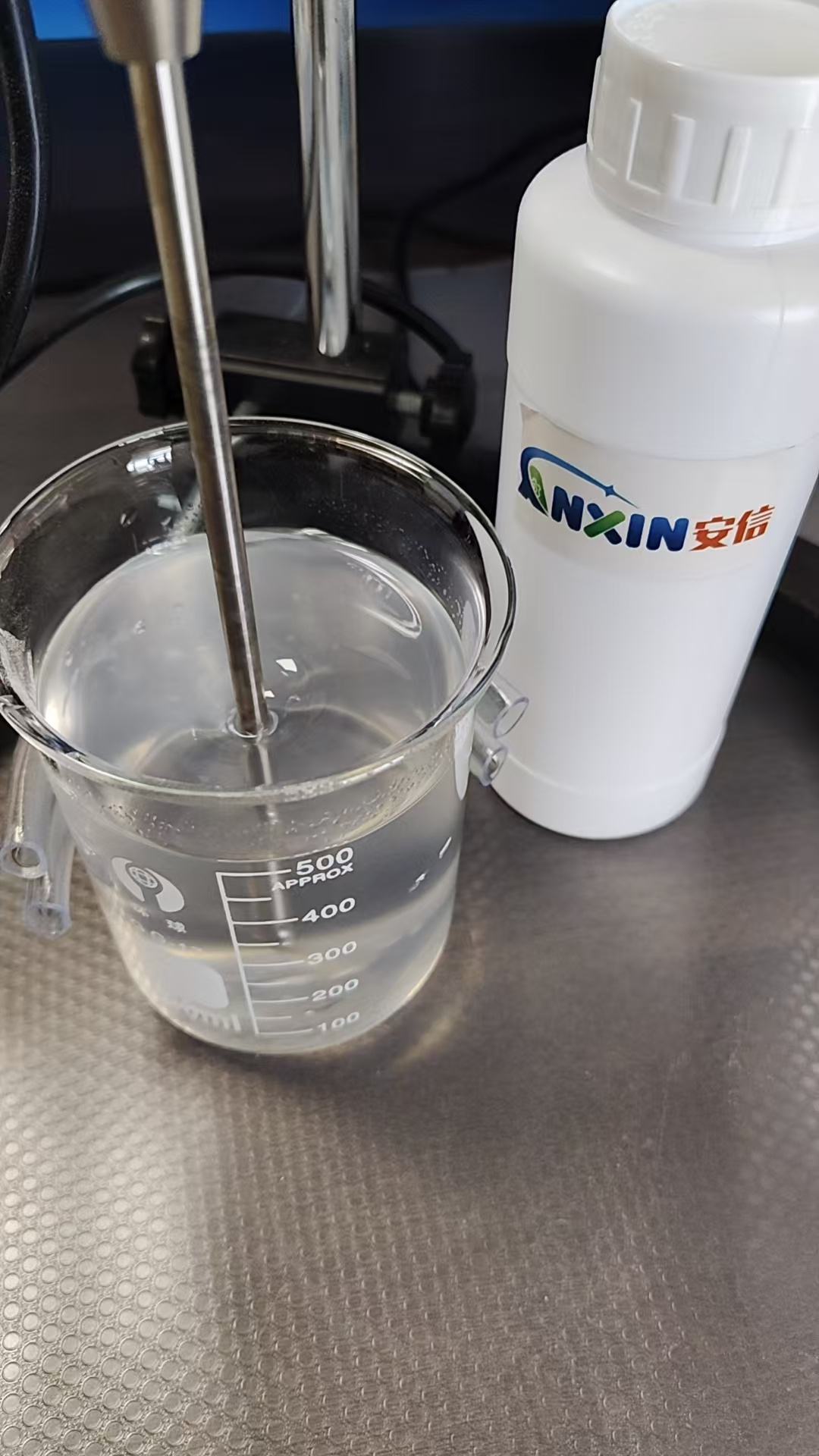

Clean beaker and stirrer

3.3. Solution Preparation

Accurately weigh 2.00 g (± 0.01 g) of HPMC sample.

Place approximately 80% of the target volume of purified water (approximately 80 mL) in a beaker and heat to approximately 80°C. Slowly and evenly sprinkle the HPMC into the beaker while stirring to avoid clumping.

Continue stirring until the HPMC is thoroughly wetted and dispersed. Then, add the remaining amount of cold water and cool to room temperature, bringing the total volume to 100 mL.

Refrigerate the solution at 4°C overnight to allow for complete swelling and eliminate air bubbles.

3.4. Viscosity Measurement

Transfer the solution to a constant temperature water bath, maintaining a temperature of 20 ± 0.1°C. Select an appropriate spindle (usually No. 2 or No. 3) and speed (usually 30 rpm).

Start the viscometer and record the reading after the needle stabilizes. Repeat each measurement three times, and take the average as the final result.

If the reading exceeds the instrument’s range, replace the spindle or adjust the concentration and re-measure.

4. Precautions

Temperature control is critical. For every 1°C increase in temperature, the viscosity decreases by approximately 2% to 3%.

The solution must be completely dissolved and free of bubbles, otherwise the reading will be low or fluctuating.

HPMC exhibits shear-thinning properties, so the speed and measurement time should be maintained consistently.

The water used must be free of impurities and ions to avoid affecting dissolution and readings.

The instrument should be calibrated regularly, and the spindle and sample container should be kept clean.

5. Analysis of Influencing Factors

Degree of Polymerization and Degree of Substitution: The higher the degree of polymerization of HPMC, the longer the molecular chain and the greater the solution viscosity. The degree of methoxy and hydroxypropoxy substitution also affects its hydrophilicity and solution structure.

Concentration: Solution concentration and viscosity are exponentially related, and even small changes in concentration can significantly affect test results. Temperature and pH: Increasing temperature decreases viscosity, while pH changes generally have little effect on HPMC viscosity because it is a nonionic cellulose ether.

Solution Aging: Viscosity may decrease slowly after prolonged storage. It is recommended that the test be completed within 24 hours of preparation.

6. Result Presentation and Application

Test results are expressed in mPa·s (milliPascals·seconds), for example, “2% solution, 20°C, 20,000 mPa·s.” In industrial applications, HPMC viscosity grades are typically expressed in thousandths, such as 400 cps and 20,000 cps. Users can select different grades based on application requirements and formulation design.

Post time: Jul-30-2025