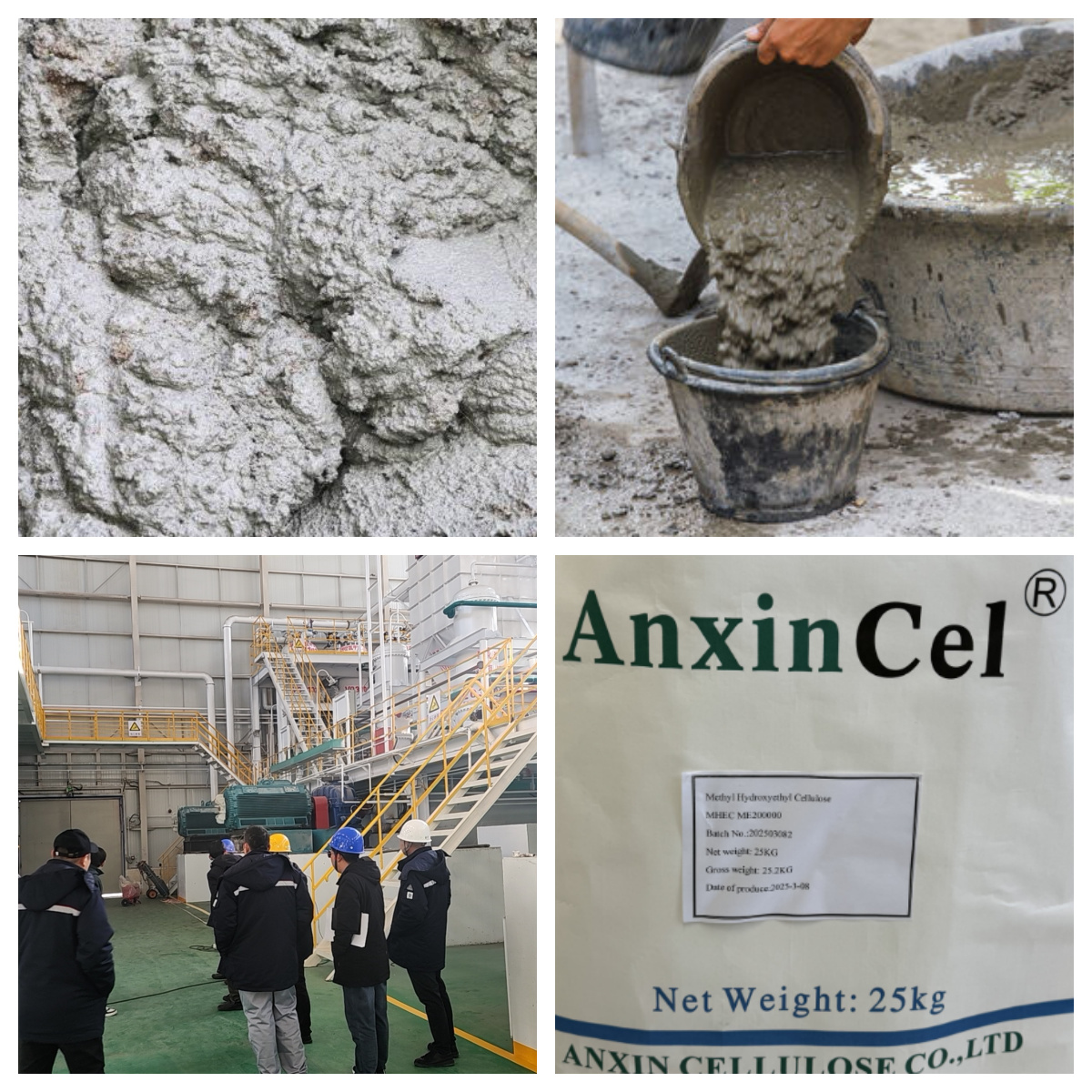

Methyl Hydroxyethyl Cellulose (MHEC) is a non-ionic cellulose ether that is widely used in building materials, especially in wet mortar, and plays an important role. Its water solubility and high molecular structure make it form a viscous solution in water, giving the mortar excellent processing properties, water retention and construction adaptability.

1. Basic properties of MHEC

MHEC is a cellulose ether derivative made by introducing methyl and hydroxyethyl groups into natural cellulose through etherification reaction. It has good water solubility, film-forming properties, water retention and adhesion. It is stable under neutral and alkaline conditions and has good biocompatibility and environmental safety.

MHEC is soluble in cold water at room temperature to form a transparent to translucent colloidal solution, and is insoluble in hot water or most organic solvents. Its dissolution process is a physical expansion-dispersion-dissolution process, and does not involve chemical reactions.

2. Dissolution process of MHEC in wet mortar

In wet mortar, MHEC is usually added to the dry mix in powder form, and then gradually dissolved during the process of adding water and stirring:

Initial stage – water absorption and swelling: MHEC particles absorb water and swell on the surface after contacting water, forming a gel coating.

Intermediate stage – dispersion and swelling: With the stirring action, part of the colloidal structure is destroyed, and MHEC begins to disperse into the entire system.

Final stage – complete dissolution: After continuous stirring and a certain period of time, MHEC is completely dissolved to form a stable polymer solution, which is evenly distributed in the mortar.

In practical applications, the dissolution rate of MHEC will be affected by the stirring intensity, water temperature, particle size, and other materials in the formula (such as cement, gypsum, sand, etc.). Proper control of these parameters can avoid the problem of agglomeration or incomplete dissolution.

3. Main functions of MHEC in wet mortar

3.1. Enhance water retention

The most significant effect of MHEC is to significantly improve the water retention capacity of mortar, reduce the rapid evaporation of free water, effectively prolong the cement hydration reaction time, thereby improving the bonding force and strength, and preventing early cracking.

3.2. Improve construction performance

Due to the lubricity and thickening effect of MHEC, the mortar has good workability, flexibility and spreadability, reducing the difficulty of construction and improving efficiency. Especially in the process of plastering and tiling, it can effectively prevent the mortar from falling and sliding.

3.3. Improve bonding performance

The colloidal network structure formed by MHEC in the mortar enhances the bonding force between the mortar and the base layer, especially when constructing on the vertical surface or top surface, keeping the mortar from falling off and enhancing the construction reliability.

3.4. Adjust consistency and fluidity

By adjusting the amount of MHEC, the consistency and rheological behavior of the wet mortar can be controlled, so that it has appropriate fluidity, which is convenient for construction, and will not affect the molding effect due to excessive flow.

3.5. Improve anti-slip performance

In applications such as tile adhesives and bonding mortars, MHEC can effectively inhibit mortar sliding, improve the positioning stability of construction, and meet the construction requirements of vertical pasting and large-size tiles.

4. Effect of MHEC dosage on mortar performance

The addition amount of MHEC is usually controlled between 0.1% and 0.5% (based on the total amount of dry materials). The effects of different dosages on mortar performance are as follows:

Low dosage (<0.1%): water retention is slightly improved, but the improvement in construction performance is not obvious.

Moderate dosage (0.2%~0.4%): Best comprehensive performance, balanced development of water retention, construction performance, and bonding strength.

Excessive use (>0.5%): It may cause excessive thickening of the mortar, reduce fluidity, and prolong the setting time.

Therefore, in the specific formula design, it is necessary to determine the optimal addition amount of MHEC through experiments to achieve the ideal use effect.

5. Synergy with other additives

MHEC can be used in conjunction with a variety of functional additives, such as:

With redispersible latex powder (VAE): jointly improve the flexibility and bonding strength of mortar;

With retarders: delay cement hydration, cooperate with MHEC to improve the construction window;

With fillers/mineral aggregates: coordinate fluidity and strength development, stabilize mortar structure.

As an important functional additive in wet mortar, hydroxyethyl methylcellulose (MHEC) plays multiple roles in thickening, water retention, enhancement and construction improvement in the mortar system through its good water-soluble properties. It is an indispensable high-performance additive in modern building materials. By scientifically selecting models and dosages, MHEC can effectively improve the comprehensive performance of mortar, meet the needs of different construction scenarios, and help green and efficient construction.

Post time: Jun-06-2025