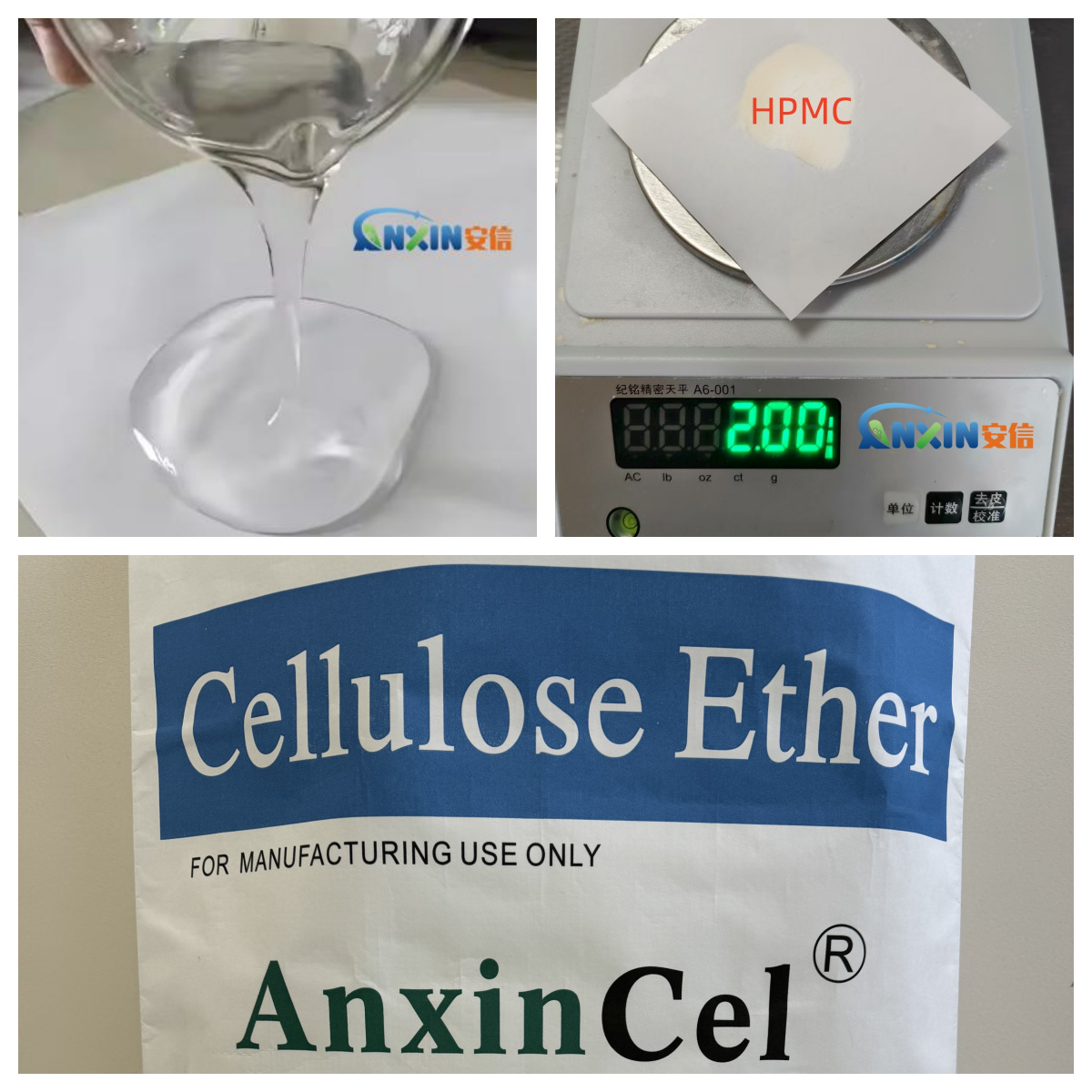

HPMC (Hydroxypropyl Methylcellulose) is a commonly used water-soluble polymer cellulose ether, widely used in industries such as building materials, pharmaceuticals, food, coatings, and daily chemicals. HPMC possesses properties such as water retention, thickening, film-forming properties, and stability. However, in practical applications, proper mixing of HPMC with water is crucial for product performance. Improper handling can easily lead to clumping, incomplete dissolution, or decreased solution performance.

1. HPMC Solubility Characteristics

A notable characteristic of HPMC is that it disperses rapidly in cold water, but forms a colloid in hot water, precipitates at high temperatures, and redissolves upon cooling. Therefore, adding HPMC directly to room temperature or hot water can easily lead to clumping, slow dissolution, or even incomplete dissolution.

2. Common Methods for Mixing HPMC with Water

2.1. Hot Water Dispersion Method (Recommended)

This method is the most commonly used and is applicable to the production of most building materials, coatings, and dry-mix mortars.

Steps:

First, heat the required amount of water to approximately 80°C.

Slowly add HPMC while stirring to evenly disperse and form a homogeneous suspension.

Continue stirring until the temperature naturally drops below 40°C. The HPMC will gradually dissolve completely, forming a transparent or translucent solution.

Advantages: Resists clumping and dissolves quickly, making it suitable for high-viscosity HPMC.

Note: Do not add HPMC directly to boiling water, as this will quickly cause it to solidify into lumps.

2.2. Cold Water Dispersion and Dissolution Method

This method is suitable for preparing solutions at room temperature.

Steps:

Slowly sprinkle the HPMC powder into cold water, stirring while spreading to prevent clumping.

After dispersion, let it sit for a period of time (usually at least 30 minutes) to allow the HPMC to absorb water and expand.

Over time, the cellulose will gradually dissolve, forming a transparent solution.

Advantages: Suitable for on-site construction or environments where heating is unavailable.

Disadvantages: Slow dissolution, requiring a longer wait time.

2.3. Mixed Powder Dry Method (Indirect Dispersion)

Applicable to dry-mix mortar or putty powder production.

Steps:

Throughly mix HPMC with other dry powder ingredients (such as cement and sand) in a mixer.

Add water and stir during application; the HPMC will gradually dissolve after dispersion.

Advantages: Avoids the difficulties of direct dissolution and facilitates mass production.

Disadvantages: The dissolution rate of HPMC is affected by mixing uniformity.

3. Common Problems and Solutions During Mixing

3.1. Problem: Agglomeration

Cause: Adding too much HPMC at once or insufficient mixing.

Solution: Add in batches, use a high-speed mixer, and use a dispersant if necessary.

3.2. Problem: Slow Dissolution

Cause: Low water temperature or insufficient mixing.

Solution: Use hot water dispersion or extend the standing time.

3.3. Problem: Foaming of the solution

Cause: Excessive mixing speed.

Solution: Add an appropriate amount of defoaming agent and reduce the mixing speed.

4. Factors Affecting HPMC Solubility

Viscosity: High-viscosity HPMC dissolves more slowly, requiring longer times or higher stirring intensity.

Degree of Substitution: The higher the degree of substitution, the better the solubility.

Water Temperature: Both too high and too low temperatures are detrimental. Cold water dispersion followed by natural dissolution, or hot water dispersion followed by cooling and dissolution, is recommended.

Mixing Equipment: Mechanical mixing is superior to manual mixing, resulting in better uniformity.

The correct method for mixing HPMC with water depends on the application and equipment conditions. Commonly used methods include hot water dispersion, cold water dispersion, and dry mixing. The key is to prevent clumping and ensure uniform dispersion and complete dissolution. In industries such as building materials, dry-mix mortar, coatings, and pharmaceuticals, a correct dissolution process not only improves product performance but also reduces production costs.

Post time: Aug-04-2025