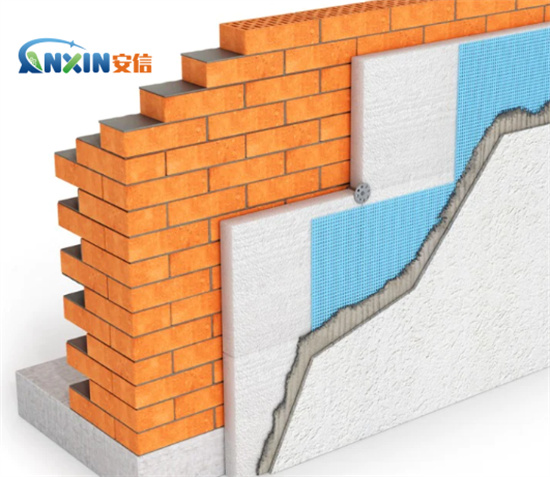

With the continuous improvement of building energy-saving requirements, the application of external wall insulation systems in the construction field is becoming more and more extensive. Expanded polystyrene particles (EPS) insulation mortar is widely used in building exterior wall insulation projects due to its good insulation performance, light weight and convenient construction. However, EPS insulation mortar has problems such as low early strength, easy cracking, and poor bonding performance, which limits its application range. In order to improve its performance, Redispersible polymer powder, as an important organic modified material, has been widely introduced into EPS insulation mortar.

1. Basic characteristics of Redispersible polymer powder

Redispersible polymer powder (RDP) is a powdered material formed by spray drying of polymer emulsion. Common types include ethylene-vinyl acetate copolymer (EVA), acrylic and styrene-acrylic. It can be redispersed into an emulsion after contact with water, and after mixing with cement, water and aggregate, it participates in the hydration process of cement to form a polymer film, which improves the flexibility and bonding strength of the material.

2. Effect of Redispersible polymer powder on working performance

Adding an appropriate amount of Redispersible polymer powder to EPS thermal insulation mortar can significantly improve its water retention and workability. The polymer film formed by RDP in mortar has a certain water retention effect, which can slow down the evaporation rate of water, increase the construction time of mortar, and is conducive to large-scale construction. At the same time, the presence of RDP makes the mortar paste more lubricated, helps EPS particles to be evenly dispersed in the matrix, and improves construction performance.

The amount of RDP added needs to be controlled within a reasonable range. If the amount added is too large, the mortar may be too fluid, which may easily cause interlayer separation and unevenness. At the same time, it may also slow down the hydration rate of cement and affect the early strength development.

3. Effect of Redispersible polymer powder on mechanical properties

Redispersible polymer powder has a significant effect on the mechanical properties of EPS thermal insulation mortar. First, RDP can form a composite structure with cement hydration products, improve the density of mortar, and significantly improve its bonding strength and crack resistance. In the interface transition zone, RDP can wrap EPS particles, improve the bonding performance between aggregate and binder, and thus improve the stability of the overall structure.

In terms of compressive strength, an appropriate amount of RDP can increase the density of mortar and improve its overall bearing capacity. However, because EPS itself is a low-strength material, its larger dosage will reduce the overall compressive strength. At this time, the role of RDP in improving compressive performance by improving interface bonding is more obvious. Therefore, in the mix design, the ratio of EPS and RDP should be reasonably weighed.

4. The effect of Redispersible polymer powder on durability

Durability is an important indicator for evaluating thermal insulation mortar materials. The polymer film formed after adding RDP can effectively reduce the intrusion of moisture and harmful ions, and improve the mortar’s impermeability, frost resistance and carbonization resistance. At the same time, the flexibility of the polymer helps to alleviate the shrinkage stress caused by external temperature and humidity changes, thereby reducing the risk of mortar cracking.

The hydrophobicity of RDP also makes EPS thermal insulation mortar have better water resistance and prolongs its service life. In rainstorm, high humidity and other environments, the performance advantages of RDP modified mortar are more obvious.

Redispersible polymer powder has a significant modification effect in EPS thermal insulation mortar. It not only improves the construction performance of mortar, enhances the bonding ability with substrate and EPS particles, but also effectively improves the mechanical properties and durability. By optimizing the type and dosage of RDP, the comprehensive performance of EPS thermal insulation mortar can be further improved to meet the energy saving and use requirements of different buildings. In future research and engineering practice, it is necessary to further explore the composite effect of RDP and other admixtures, as well as its long-term performance under different environmental conditions.

Post time: Apr-26-2025