Redispersible polymer powder (RDP), as a core organic additive in modern dry-mix mortars, is widely used in various systems such as tile adhesives, putty powders, exterior wall insulation mortars, self-leveling mortars, and waterproof mortars due to its excellent bonding properties, flexibility, and modification capabilities. Essentially, it is a solid powder made by spray-drying a polymer emulsion. Upon contact with water, it can redisperse into a stable emulsion, thus forming a continuous organic polymer film during the mortar hardening process, significantly improving the overall performance of the mortar.

1. Core Mechanism of RDP in Improving Mortar Performance

1.1. Enhancing Bond Strength

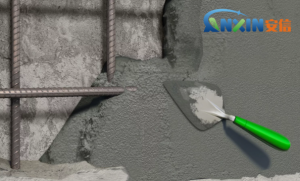

The polymer film formed by RDP after mortar hardening has high adhesion and good ductility, forming a strong bonding bridge on the substrate surface, significantly improving the adhesion between the mortar and materials such as concrete, bricks, EPS boards, and tiles. The role of RDP is particularly crucial on low-absorption or smooth substrates.

1.2. Enhanced Flexibility and Crack Resistance

Traditional cement-based materials are highly brittle and prone to cracking due to temperature changes and substrate deformation. The polymer in RDP disperses into the mortar pores, forming a flexible network structure, reducing the material’s elastic modulus, and enhancing its resistance to deformation, thus significantly improving the mortar’s crack resistance.

1.3. Improved Workability

RDP makes the mortar finer and smoother, improving workability and application feel. Its improved water retention and extended open time facilitate smoother construction, increasing efficiency and quality stability.

1.4. Enhanced Water and Weather Resistance

The polymer film possesses excellent hydrophobicity and water resistance, reducing mortar water absorption and thus improving resistance to hydration and freeze-thaw cycles. In exterior wall applications, RDP helps improve the weather resistance of coatings and mortars, maintaining their stability under long-term exposure.

2. Applications of Redispersible Polymer (RDP) in Different Mortar Systems

2.1. Tile Adhesive

RDP is an essential component of tile adhesive, significantly improving adhesion, anti-slip properties, and flexibility. For large-format tiles, low-absorption tiles, or vitrified tiles, high polymer content RDP ensures a firm bond and prevents hollow areas and detachment.

2.2. Exterior Wall Insulation Mortar (EPS/XPS Adhesive, Finishing Mortar)

In insulation systems, RDP provides the necessary flexibility and bond strength, allowing the mortar to adhere tightly to EPS/XPS boards. It also improves the crack resistance and impact resistance of the finishing layer, ensuring the long-term stability of the insulation system.

2.3. Waterproof Mortar

RDP forms a dense polymer film within the mortar, reducing capillary porosity and improving impermeability. Synergistically working with cement hydration products, it significantly enhances the flexibility and durability of the waterproof layer.

2.4. Self-Leveling Mortar

In self-leveling systems, RDP improves the early strength, fluidity, and bonding properties of the mortar while reducing brittleness, resulting in more stable floor construction and higher surface strength.

2.5. Putty Powder

Adding RDP to putty powder enhances adhesion, anti-chalking properties, and sanding feel, resulting in a smoother, more refined wall surface and improved water resistance and durability.

2.6. Repair Mortar and Interface Agent

RDP improves the adhesion and crack resistance of repair materials, making them more stable and reliable in applications such as old concrete repair and interface treatment.

3. Precautions for Using Redispersible Polymer Powder

Select the appropriate RDP type and dosage based on the function of the mortar system;

Combining with cellulose ethers (HPMC/MHEC), starch ethers, etc., can further optimize water retention, workability, and sag resistance;

Store in a dry environment to avoid moisture and clumping;

Ensure thorough dispersion during mixing to achieve stable performance.

Post time: Dec-01-2025