Tile adhesives have revolutionized the construction and tiling industry by replacing traditional methods like cement mortar. Among the leading high-performance adhesives in the market is AnxinCel® C1 and C2 tile adhesive, specifically formulated for ceramic, porcelain, and natural stone tiles. These adhesives comply with the EN 12004 standards for ceramic tile adhesives, which classify products based on performance criteria, especially adhesion strength.

1. Understanding Tile Adhesive Classifications (EN 12004)

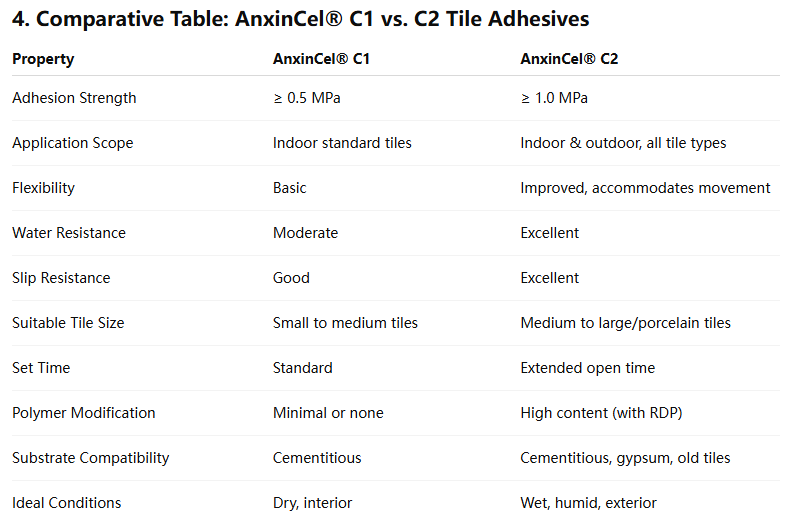

To fully appreciate AnxinCel® tile adhesives, it is essential to understand the C1 and C2 classification:

C1 – Normal Cementitious Adhesive

Minimum adhesion strength: ≥ 0.5 MPa

Suitable for standard indoor ceramic tile installations on concrete and cementitious surfaces.

C2 – Improved Cementitious Adhesive

Minimum adhesion strength: ≥ 1.0 MPa

Enhanced performance: higher bond strength, reduced slip, extended open time, etc.

Suitable for demanding installations: larger tiles, low-porosity tiles (porcelain), and exterior applications.

2. AnxinCel® C1 Tile Adhesive: Features & Applications

2.1 Composition

AnxinCel® C1 is formulated from:

High-quality Portland cement

Graded mineral fillers

Performance-enhancing additives such as HPMC (Hydroxypropyl Methylcellulose) and RDP (Redispersible Polymer Powder) to ensure smooth workability, consistent bonding, and ease of application.

2.2 Key Features

Good adhesion strength (≥0.5 MPa)

Easy mixing and smooth application

Extended open time for user convenience

Non-slip properties for wall applications

Good water retention, minimizing premature drying

Economical and ideal for indoor use

2.3 Recommended Applications

Interior wall and floor tiling

Standard ceramic tile installations

Suitable substrates: cement mortar, concrete, screeds

Dry areas such as living rooms, bedrooms, hallways

3. AnxinCel® C2 Tile Adhesive: Enhanced Performance

3.1 Composition

AnxinCel® C2 contains:

Modified cementitious binder

Graded sand

High-performance additives like:

Advanced HPMC for water retention and consistency

RDP for flexibility and improved bonding

Silica fume or microsilica for increased density and durability

3.2 Key Features

High adhesion strength (≥1.0 MPa)

Flexibility to accommodate slight substrate movement

Extended open time and adjustment time

Water and frost resistance for external applications

Non-slip characteristics for vertical surfaces

Suitable for porcelain and vitrified tiles

High shear strength, especially in wet and exterior environments

3.3 Recommended Applications

Large-format tiles (ceramic, porcelain)

External wall and façade cladding

Wet areas: bathrooms, kitchens, pools

Floors with underfloor heating

Heavy traffic areas in commercial and public buildings

5. Installation Guidelines for AnxinCel® Adhesives

5.1 Surface Preparation

Surface must be clean, sound, and free from dust, oil, and loose particles.

Dampen absorbent surfaces but avoid water pooling.

5.2 Mixing

Mix powder with clean water at the recommended ratio (typically 4.5–5.5 L of water per 20 kg bag)

Use a slow-speed electric mixer to ensure a lump-free, homogenous mix.

Rest the mix for 5–10 minutes, then remix before application.

5.3 Application

Apply the adhesive using a notched trowel appropriate for tile size.

Press tiles firmly into position with slight movement to ensure full contact.

Grouting can be done after 24 hours under normal conditions.

5.4 Coverage

Approximate coverage: 4–6 kg/m² depending on trowel size and substrate smoothness.

6. Packaging and Storage

Packaging:

Standard: 20 kg moisture-proof bags

Storage:

Store in a cool, dry area

Shelf life: 12 months in original sealed packaging

7. Environmental and Safety Considerations

AnxinCel® adhesives are formulated with low-VOC content and are environmentally friendly. Standard safety practices should be followed:

Wear gloves and protective gear

Avoid inhaling dust

Wash hands thoroughly after use

Material Safety Data Sheets (MSDS) are available upon request.

8. Why Choose AnxinCel® C1 and C2 Adhesives?

Quality Assurance: Meets and exceeds EN 12004 standards.

Reliable Performance: Trusted by contractors and tiling professionals.

Versatility: Suitable for a wide range of tiles and surfaces.

Cost Efficiency: High coverage and minimized wastage.

Brand Reputation: AnxinCel® is known for consistency and innovation in dry-mix mortar technology.

AnxinCel® C1 and C2 tile adhesives provide construction professionals and contractors with high-performance, reliable, and user-friendly solutions for a wide variety of tiling applications. Whether for routine indoor installations or complex exterior facades and wet area challenges, AnxinCel® products are engineered to deliver excellent adhesion, durability, and finish. Choosing the right type—C1 for standard jobs or C2 for demanding conditions—ensures optimal performance and long-lasting results.

Post time: Jun-18-2025