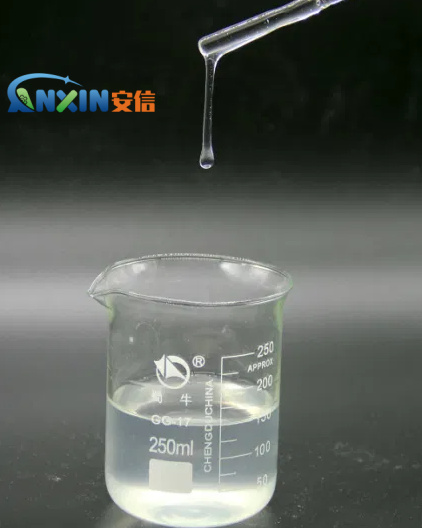

I-Hydroxypropyl methylcellulose (HPMC)i-polymer encibilika emanzini esetshenziswa kabanzi kwezemithi, ukwakhiwa, ukudla, izimonyo neminye imikhakha. Impahla yayo ye-viscosity iyipharamitha ebalulekile yokukala ukuziphatha kwayo kwe-rheological ngaphansi kwezindawo ezahlukene. Ukuqonda impahla ye-viscosity yesisombululo samanzi se-HPMC kusisiza ukuthi siqonde kangcono ukuziphatha nokusebenza kwayo ezinhlelweni ezihlukahlukene.

1. Isakhiwo samakhemikhali kanye nezakhiwo ze-HPMC

I-HPMC itholakala ngokuguqulwa kwamakhemikhali kwe-cellulose yemvelo, ikakhulukazi eyakhiwe yi-hydroxypropylation kanye ne-methylation yama-molecule e-cellulose. Esakhiweni samakhemikhali se-HPMC, ukwethulwa kwamaqembu e-methyl (-OCH₃) kanye ne-hydroxypropyl (-OCH₂CHOHCH₃) kuwenza ancibilike emanzini futhi abe nekhono elihle lokulungisa i-viscosity. Ukusebenza kwe-viscosity yesisombululo sayo se-aqueous ekugxilweni okuhlukene kanye namazinga okushisa athintwa izici eziningi ezifana nesisindo se-molecular, degree of substitution, ukugxila kwesisombululo, njll.

2. Ubudlelwano phakathi kwe-viscosity nokugxila

I-viscosity yesisombululo samanzi se-AnxinCel®HPMC ivamise ukukhuphuka ngokugxila okukhulayo. Lokhu kungenxa yokuthi ekugxilweni okuphezulu, ukusebenzisana phakathi kwama-molecule kuyathuthukiswa, okuholela ekwandeni kokuphikiswa kokugeleza. Kodwa-ke, izici ze-solubility kanye ne-viscosity ze-HPMC emanzini nazo zithinteka ngesisindo samangqamuzana. I-HPMC enesisindo samangqamuzana aphezulu ngokuvamile ibonisa i-viscosity ephakeme, kuyilapho isisindo samangqamuzana esiphansi siphansi.

Ezimweni eziphansi: Isixazululo se-HPMC sibonisa i-viscosity ephansi ekugxilweni okuphansi (njengangaphansi kuka-0.5%). Ngalesi sikhathi, ukusebenzisana phakathi kwama-molecule akunamandla futhi uketshezi luhle. Imvamisa isetshenziswa ezinhlelweni ezifana nama-coatings kanye nokukhululwa okuqhubekayo kwezidakamizwa.

Ekugxilweni okuphezulu: Ezimweni eziphakeme (ezifana no-2% noma ngaphezulu), i-viscosity yesisombululo samanzi se-HPMC sikhula kakhulu, okubonisa izakhiwo ezifana nezixazululo ze-colloidal. Ngalesi sikhathi, i-fluidity yesisombululo ingaphansi kokumelana okukhulu.

3. Ubudlelwano phakathi kwe-viscosity nezinga lokushisa

I-viscosity yesisombululo samanzi se-HPMC izwela kakhulu izinga lokushisa. Njengoba izinga lokushisa likhuphuka, ukunyakaza phakathi kwama-molecule amanzi kuyanda, futhi ukuxhumana phakathi kwama-molecule e-HPMC kuba buthaka, okuholela ekunciphiseni kwe-viscosity. Lesi sici senza ukusetshenziswa kwe-HPMC kumazinga okushisa ahlukene kubonise ukulungiswa okuqinile. Isibonelo, ngaphansi kwezimo zokushisa eziphakeme, i-viscosity ye-HPMC ivame ukuncipha, okubaluleke kakhulu enqubweni yemithi, ikakhulukazi kumafomu omthamo wokukhishwa okuqhubekayo kwezidakamizwa, lapho ukuguquka kwezinga lokushisa kungase kuthinte ukuzinza nomphumela wesixazululo.

4. Umthelela we-pH ku-Viscosity

I-viscosity yesisombululo samanzi se-HPMC ingase futhi ithintwe inani le-pH lesixazululo. Nakuba i-HPMC iyinto engeyona i-ionic, izakhiwo zayo ze-hydrophilicity kanye ne-viscosity zithinteka kakhulu ukwakheka kwamangqamuzana kanye nemvelo yesisombululo. Kodwa-ke, ngaphansi kwezimo ezine-acidic ngokweqile noma ezine-alkaline, ukunyibilika kanye nesakhiwo samangqamuzana e-HPMC singashintsha, ngaleyo ndlela kuthinte i-viscosity. Isibonelo, ngaphansi kwezimo ze-acidic, ukuncibilika kwe-HPMC kungase kube buthaka kancane, okuholela ekwandeni kwe-viscosity; ngenkathi ngaphansi kwezimo ze-alkaline, i-hydrolysis ye-HPMC ethile ingase ibangele isisindo sayo samangqamuzana sehle, ngaleyo ndlela yehlise i-viscosity yayo.

5. Isisindo se-Molecular and Viscosity

Isisindo samangqamuzana singenye yezinto ezibalulekile ezithinta i-viscosity yesisombululo samanzi se-HPMC. Isisindo samangqamuzana esiphezulu sikhulisa ukubopha kanye nokuxhumanisa phakathi kwama-molecule, okuholela ekwandeni kwe-viscosity. Isisindo samangqamuzana aphansi i-AnxinCel®HPMC inokunyibilika okungcono emanzini kanye ne-viscosity ephansi. Izidingo ezihlukene zohlelo lokusebenza ngokuvamile zidinga ukukhethwa kwe-HPMC enesisindo samangqamuzana ahlukene. Isibonelo, ezimbotsheni nasezinamathiselwe, i-HPMC enesisindo esikhulu samangqamuzana ivame ukukhethwa ukunamathela okungcono kanye ne-fluidity; ngenkathi kumalungiselelo emithi, i-HPMC enesisindo esiphansi se-molecular ingase isetshenziselwe ukulawula izinga lokukhululwa kwezidakamizwa.

6. Ubudlelwano phakathi kwe-shear rate kanye ne-viscosity

I-viscosity yesisombululo samanzi se-HPMC ngokuvamile siyashintsha ngesilinganiso sokugunda, okubonisa ukuziphatha okujwayelekile kwe-pseudoplastic rheological. I-Pseudoplastic fluid iwuketshezi olubonakala luyancipha kancane kancane ngokunyuka kwezinga lokugunda. Lesi sici senza isixazululo se-HPMC sigcine i-viscosity ephezulu ngezinga eliphansi lokugunda uma sisetshenziswa, futhi sithuthukise uketshezi ngezinga eliphakeme lokugunda. Isibonelo, embonini yokugqoka, isixazululo se-HPMC ngokuvamile sidinga ukukhombisa i-viscosity ephakeme ngenani eliphansi le-shear lapho sisetshenziswa ukuze kuqinisekiswe ukunamathela nokulinganisa kwe-coating, kuyilapho ngesikhathi senqubo yokwakha, kuyadingeka ukwandisa izinga le-shear ukuze kube noketshezi oluningi.

7. Isicelo kanye nezici ze-viscosity ze-HPMC

Izici ze-viscosity zeI-HPMCyenze isetshenziswe kabanzi emikhakheni eminingi. Isibonelo, embonini yezemithi, i-HPMC ivame ukusetshenziswa njenge-ejenti yokukhululwa okuqhubekayo kwezidakamizwa, futhi ukulawulwa kwayo kwe-viscosity kusetshenziselwa ukulawula izinga lokukhululwa komuthi; embonini yezokwakha, i-HPMC isetshenziswa njenge-thickener ukuze kuthuthukiswe ukusebenza kahle kanye ne-fluidity of mortar and adhesives; embonini yokudla, i-HPMC ingasetshenziswa njenge-thickener, emulsifier kanye ne-stabilizer ukuthuthukisa ukunambitheka nokubukeka kokudla.

Izici ze-viscosity zesisombululo samanzi se-AnxinCel®HPMC ziwukhiye wokusetshenziswa kwayo emikhakheni ehlukene. Ukuqonda ubudlelwano bayo nezinto ezifana nokugxilisa ingqondo, izinga lokushisa, i-pH, isisindo samangqamuzana nezinga lokugunda kubaluleke kakhulu ekuthuthukiseni ukusebenza komkhiqizo kanye nokwenza ngcono imiphumela yohlelo lokusebenza.

Isikhathi sokuthumela: Jan-27-2025